Lightweight Belting

Lightweight Belting

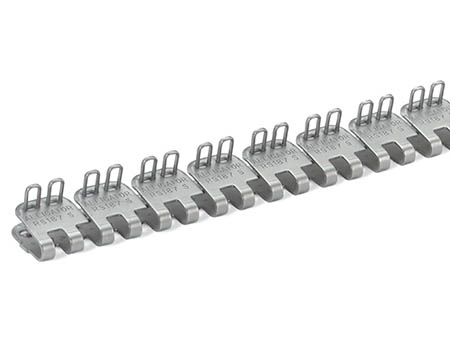

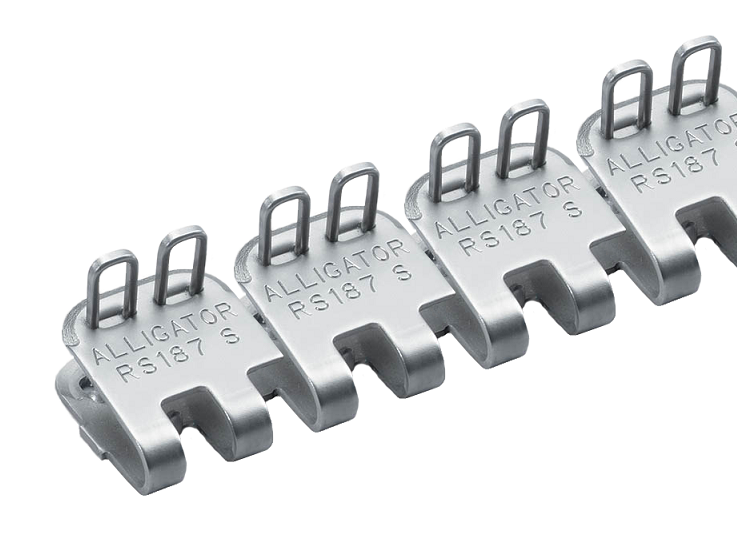

Alligator Ready SetTM Staple

The Alligator Ready SetTM Staple, featuring one-piece fastener strips with pre-inserted staples, reduces installation time by eliminating the need to handle and load individual staples. The result is a strong splice that resists impact damage, as well as a smooth, unrippled joint that simplifies hinge pin insertion.

Staples penetrate between carcass fibers without severing them. Staples are hammer- driven through the belt and then clinched crosswise to prevent belt tension from pulling against and unclinching the staples.

Designed for belts from 1/16” (1.5mm) to 1/4” (6.4mm), Alligator Ready Set installation requires only a hammer and a lightweight installation tool that can be easily carried to and from the job site. Plus, the new Quad Staple DriverTM allows for the installation of four staples at one time, cutting installation time by 50%.

Choose the material that matches your application. Steel: Standard fastener material is suitable for most applications. Plated for rust and corrosion resistance. Stainless Steel: Type 316 provides extra resistance to abrasion, magnetic attraction, and corrosion from acids and chemicals. Also excellent for high-sanitary requirements. MegAlloy: Superior resistance to wear and abrasion, providing several times the service life of steel. Not recommended where subject to impact or corrosion. Magnetic Stainless Type 430: For use with magnetic separators, and provides resistance to wear and abrasion. Plate, staples and hinge pins are all constructed from magnetic stainless steel.

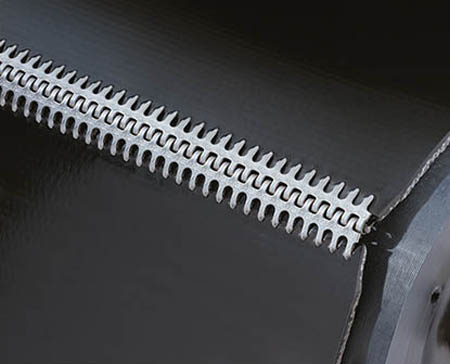

Alligator Lacing

For easy, economical installation and an exceptionally smooth joint, choose Alligator Belt Lacing Fastener System. Steel or stainless lacing is available in continuous lengths to fit any belt width. The hammer-applied splice requires no special installation tools and is ideal for low- volume users with belts up to 1/2” (13mm) thick.

One-piece design provides uniform tension across the full belt width. Also helps ensure that no loose pieces work themselves out of the belt and into conveyed product.

Alligator Belt Lacing can operate over pulleys as small as 1” (25mm) in diameter, or on belts with mechanical fastener ratings to 200 PIW (35 kN/m).

Alligator Belt Lacing is available for both conveyor belts and transmission belts. Both types are available in steel or Type 316 stainless steel. Steel: Standard fastener material is suitable for most applications. 00, 1 and 7 lacing is plated for rust and corrosion resistance. Stainless Steel: Type 316 provides extra resistance to abrasion, magnetic attraction, and corrosion from acids and chemicals. Also excellent for high sanitary requirements.

Alligator Plastic Rivet

For applications where metal belt fasteners cant be used, the Alligator Plastic Rivet Fastener System is a long-lasting, easy-to-install solution for light-duty applications. Our sturdy non- metallic fastener is also a low-cost alternative to the time and expense associated with vulcanization.

Fastener plate leading edges are beveled to ensure a smooth, low-profile splice. The one-piece fastener features an integrated design with rivets molded right into the fastener top plate - fast belt replacement means reduced downtime and increased productivity. Plus, the smooth surface is easy to clean.

Design permits use on applications with minimum pulley diameters as small as 1-1/2” (38mm) and on belts 1/32” to 1/8” (0.8-3.2mm) thick.

Choose the material that matches your application. UV-resistant black delivers extended life in outdoor applications. FDA- accepted white plastic is suitable for food and pharmaceutical processing applications, and resists weak acids, alkali, hydrocarbons, ester solvents, and alcohols. Both materials can be used in applications from -20F to 180F (-29C to 82C).